Many

mining plant operators are unsure of how their plants should be classified in

terms of the Ex classifications. “Pratley has developed extensive expertise in the

demands placed on electrical termination equipment used in hazardous areas,”

comments Marketing Director Eldon Kruger.

Many

mining plant operators are unsure of how their plants should be classified in

terms of the Ex classifications. “Pratley has developed extensive expertise in the

demands placed on electrical termination equipment used in hazardous areas,”

comments Marketing Director Eldon Kruger.

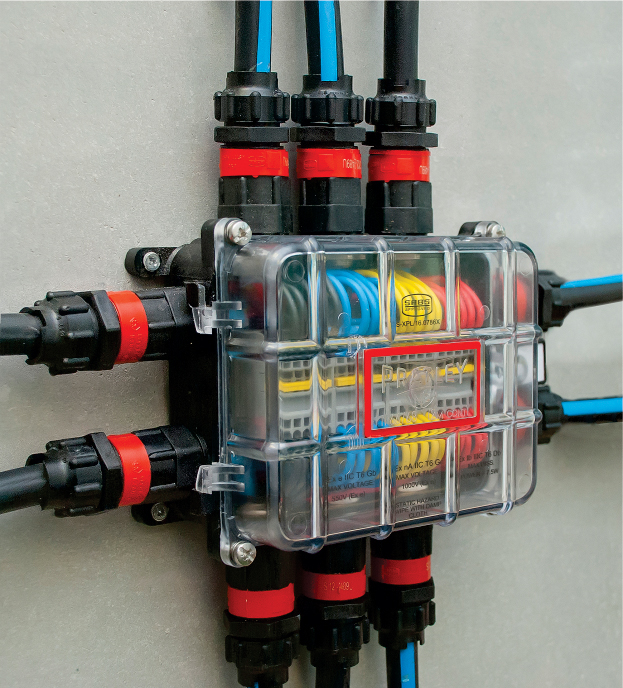

Pratley is a long-established manufacturer of electrical apparatus for use in hazardous and non-hazardous industrial applications such as the mining industry. It shares its expertise with the industry through regular seminars and through ongoing product developments.

According to the South African National Standards (SANS) and the International Electrotechnical Commission (IEC), a hazardous area is where there is a risk of explosion due to the presence of flammable dust or explosive gases or vapours. To ensure the health and safety of employees working in such hazardous areas, it is critical that all electrical equipment used does not pose a risk of ignition in operation or in the event of any failure.

Hazardous areas are defined by three main criteria:

· The type of hazard

· The likelihood of the hazard being present in flammable concentrations

· The (auto) ignition temperature of the hazardous material

Different zones are classified according to the potential source of ignition and the likelihood of the hazard being present in flammable concentrations. Zones 0, 1, and 2 refer to the presence of explosive gases or vapours, while Zones 20, 21, and 22 refer to zones where explosive dust is present.

Zone 0 denotes a constant hazard; Zone 1 an ongoing risk of an explosion occurring during normal operations; and Zone 2 a risk arising only in the event of abnormal operational situations. The same applies with respect to dust Zones 20, 21, and 22.

T-ratings present a further qualifying classification relating to the auto-ignition temperature of the hazardous material. T-ratings indicate the temperature class of a hazardous area and the electrical apparatus to be used in the area. A junction box, for example, needs to be of a design and material so it does not heat up and presents an ignition risk.

Temperature ratings range from T1 (< 450°C) to T6 (< 85°C). T6 is stipulated for use in the most dangerous areas, for example in zones coded Gas Group IIC gas – Carbon Disulphide, which has an auto-ignition temperature of 90°C.

In specifying electrical equipment with respect to temperature ratings, consideration needs to be given to the heat generated by the electrical equipment itself during normal operation and the ambient temperature. In addition, safety-critical electrical termination equipment like flameproof Ex d junction boxes must be designed to contain the pressure of any explosion.

The junction box must incorporate a specific flame path, bearing in mind that all the cable gland entries serve as flame paths. Ex d flameproof junction boxes need to be able to withstand a pressure up to 30 bar or higher to contain the force of an explosion.

There are further qualifying codes for electrical apparatus indicating different protection concepts or methods of protection: ‘Ex i’ indicates intrinsic safety; ‘Ex d’ indicates flameproof equipment; ‘Ex e’ indicates increased safety. SANS 10108 sets out the definitions for electrical apparatus for use in hazardous areas.

Marking electrical equipment for hazardous areas is

fundamental to identifying what can be used where. All Ex equipment has to be

marked with the particular information supporting its safe use. ATEX, SANS, and

IEC classifications, codes, and markings all vary slightly. Unless the plant

operator knows what he or she is looking for, equipment markings can cause a

lot of confusion. Therefore, it is essential that plant operators understand

the markings on electrical apparatus.

Marking electrical equipment for hazardous areas is

fundamental to identifying what can be used where. All Ex equipment has to be

marked with the particular information supporting its safe use. ATEX, SANS, and

IEC classifications, codes, and markings all vary slightly. Unless the plant

operator knows what he or she is looking for, equipment markings can cause a

lot of confusion. Therefore, it is essential that plant operators understand

the markings on electrical apparatus.

There are a number of different inspection authorities and test houses that deal with Ex equipment in South Africa and are authorised to issue IA certificates confirming the use of Ex equipment. Each certificate carries a unique number and includes particular prefixes and suffixes denoting specific qualifying factors.

The code of practice for Ex equipment inspection processes stipulates that inspection should be conducted within a period not exceeding two years, or as otherwise indicated by the risk assessment applicable to any given installation. Inspections range through different levels:

· Visual inspection confirms that the correct equipment is being used in the correct zone, with the correct markings applicable to that zone.

· Close inspection involves taking a closer hands-on look at equipment, checking connections, and ensuring all is in good working order.

· Detailed inspection entails taking the equipment apart to inspect it thoroughly and decide on repair or replacement as necessary.

Maintenance inspections are mostly carried out

in-house. However, certification testing should be carried out on all new

equipment, replacement equipment, or where changes are made, or equipment is

repaired.

Maintenance inspections are mostly carried out

in-house. However, certification testing should be carried out on all new

equipment, replacement equipment, or where changes are made, or equipment is

repaired.